Simple to operate. Unskilled operators can quickly learn to produce perfect drill points. Set up and grinding is fast and the web can be thinned in a few seconds.

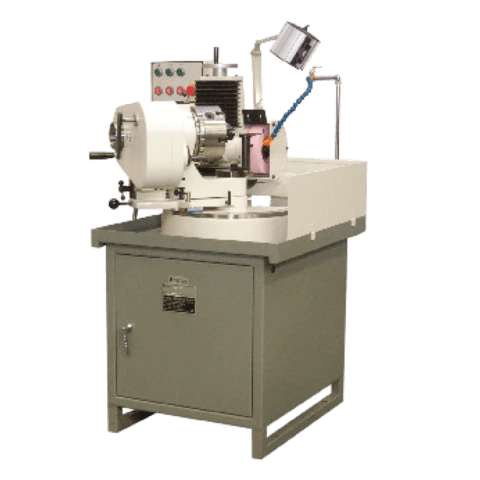

Accurate. Rugged construction and precision components ensure accuracy and repeatability over many years. Heavy duty compound slides and one-piece cast iron base increase rigidity and minimise vibration. The workhead incorporates precision needle roller and thrust bearings, while the main chuck spindle utilises a rotalin bearing giving less than 0.005 mm deflection. The six-jaw chuck accurately centres the drill to ensure each cutting lip is equally ground for both length and angle to develop a precision point.

Versatile. A wide range of points can be ground: Right-hand and left-hand drills with point angles between 40o and 180o, standard, centre drills, carbide drills, step and subland drills, taps and reamers. Also a number of NC self-centre points can be ground, including split, four-facet and spiral. Cutting lips can also be corrected.

|

MODEL |

ZB-50N (DUAL CAM) |

ZB80 |

|

Drill Size |

(Ø3-Ø50mm) straight or taper shank (1,2,3,4,5,6 flute) |

Ø4mm-Ø80mm(1,2,3,4,5,6 flute)

|

|

Point Angles |

40º-180º |

40º-180º |

|

Clearance angle |

0º-18º |

0º-18º |

|

Motor |

0.38kw(0.5hp) single or 3 phase totally enclosed fan cooled |

1.13kw(1.5hp) |

|

Grinding Wheels |

Main wheel 7” x 1 ¼” x 1 ¼” |

Main wheel(180mm x 50mm x 31.75mm) |

|

|

(180mm x 32mm x 31.75mm) |

|

|

|

Point thinning dish wheel |

Point thinning dish wheel |

|

|

6 5/8”x7/8”x1 1/4” |

|

|

|

(165mm x 21mm x 31.75mm) |

(165mm x 21mm x 31.75mm) |

|

Grinding the End of End Mills |

2,3,4,6,12 flute |

2,3,4,6,12 flute |

|

X Stroke |

240mm |

- |

|

Y Stroke |

180mm |

- |

|

Net Weight |

300kg |

380kg |

|

Dimensions |

970mm x 910mm x1370mm |

1090mm x 1120mm x 1370mm |

STANDARD ACCESSORIES

• 6 Jaw Self-Centering Chuck.

• Grinding Wheel (recessed one side)

• “Dish” Grinding Wheel for Point Thinning.

• Grinding Wheel Flange and Balancing Weight.

• Two Grinding Wheel Diamond Dressers (one angle dresser and one straight).

• No. 1,2,3,4 Morse Taper Sleeve for ZB50

• No. 2,3,4,5,6 M.T Sleeve for ZB80

• Cam No.4 for Point Angle (40º-180º)

• Cam No.6 for Step Drill

• Cam No.8 for 4 Flute Taps or Reamers

• A.C. Motor.

• Tools for General use.

• Service/Instruction Manual.

• Work Light (12 Volts)

OPTIONAL ACCESSORIES

• Flood Coolant System. (Increases wheel life and prevents burning of drill)

• Silicon Carbide and Diamond Wheels for Carbide Drills.

• Radial Relief Attachment. Relieves Radius of Pilot to Produce Lands. Also for Sharpening End Mills

• Wheel Balancer & Arbor

• Auto Feed Mechanism (pre-setting feeding quantity)

• Powered Work head for Automatic Rotation & Cam Action (rpm 0-58 step less)

• Extra Grinding Wheel Flange for Cup Wheel

• Cup Grinding Wheel

• Cam for Left Hand Drills

• Cam for Spiral Point Drills

• Cam for Sheet metal Point Drills

• Cam for 1 Flute Grinding

• Cam for 3 Flute Grinding

• Cam for 5 Flute Grinding

• Cam for 6 Flute Grinding